10 Firsts @ MATT: Embracing Complex Design Demands Through Creative Construction

MATT's Teams Tackle 10 Construction Firsts To Bring New Icons To Life

Sometimes, the simplest element of a design can prove the most mind-boggling to execute. MATT Construction revels in executing daring visions through creative construction. Along the way to building some of California’s most iconic commercial and residential structures, teams on and off the jobsite have encountered numerous projects that have led them into uncharted territory. Embracing these moments as opportunities for innovation has given MATT’s staff and collaborators a unique set of tools and skills to draw from — not to mention memorable moments to share, both nail-biting and first-pumping alike.

The Fan Wall @ Caltech’s Center for Autonomous Systems and Technologies (CAST) Lab

A major part of this revolutionary design-build laboratory endeavor involved the creation of the aerodrome, a covered, semi-outdoor arena to operate single or formation-flying drones under a range of conditions. To put these pioneering robots to the ultimate test, the team devised a first-of-its-kind, 10′ x 10′ fan wall consisting of 1,296 independently controllable microfans that could simulate rain, hail, sandstorms, turbulence and gust, generating wind speeds of up to 44 mph. Creative engineering and construction mitigated some of the major concerns, such as how to air circulation and noise generation.

Photo credit: Raimund Koch

Rippling Steel Ribbon Exterior @ Petersen Automotive Museum

A standout along LA’s iconic Wilshire corridor, the revitalized Petersen Automotive Museum’s exterior embodies the spirit of movement, power and grace. Its undulating steel ribbons, set over a fiery red edifice of corrugated aluminum, make the façade a conversation piece worthy of its subject. The team first strengthened the upright pile foundations to make sure the building could support 135-ton steel and aluminum bands, then designed specially crafted steel trees to bear the weight over the rooftop event deck. Read the full story of how the consultant team achieved this ambitious vision through careful use of 3D modeling technology along with virtual and physical mockups here.

Levitated Mass Suspended Sculpture @ LACMA

After decades of searching, Earth Artist Michael Heizer found the right boulder to realize his vision, Levitated Mass, in a minimalistic, man-made tunnel at LACMA. The epic rock weighs around 680,000 pounds and towers over bystanders at over 20 feet tall. Heizer wanted viewers walking beneath the boulder to feel as if it were hanging in space just above them, which required careful planning, the construction of continuous walls 456 feet long and 18 feet high at points, bearing tight vertical joints and no horizontal joints. All this happened without the use of form ties during the pouring and curing stages, because they would have left scars in the concrete and diminished the illusory ‘floating’ sensation.

Dinesen Oak Floor Galleries @ Hammer Museum

As part of the Hammer Museum’s series of renovations, MATT’s team gutted three massive upper-level galleries. The clean, open aesthetic entailed high ceilings, skylights and highly specialized flooring: wide oak planks from Denmark gleaming with a white oil finish. Danish craftspeople worked side by side with MATT’s team to help install these stunning 11″ Dinesen oak floorboards according to their specific techniques. The feat marked the largest such installation in all of California.

Photo credit: Nathaniel Riley

Raised Paver Floor System @ The Music Center Plaza

Downtown LA’s revitalized Music Center Plaza rests on a rooftop above a parking facility. To make the floor space of the future performance and event venue accessible and on-level with the five plaza buildings already in place, and to have a system that the existing structure could structurally support, the team had to create a custom vehicular-rated access floor system. The system relies on metal pedestals, overlaid with joists, then layered with metal grates and topped with pavers. The work required meticulous work done by hand, with over 100 crew members on site fitting each piece into place. The resulting raised floor can withstand the weight of a fully loaded forklift, meeting the owner’s needs for future event planning and operations.

Protective Synthetic Turf @ Marlborough School

Marlborough School’s Arden Project saw a major enhancement of campus athletic facilities, leveraging cutting-edge technology to elevate the breadth and safety of their offerings. The revolutionary synthetic-turf laid down at Booth Field was among the first of its kind and features a Brock YSR performance base layer with cork infill. The material takes the relative weight of young athletes, who exert less force, into account. A white foam layer engineered for energy attenuation at lower loads can still maintain the proper stiffness for foot stability and speed, resulting in reduced impact from potential head-to-surface collisions. The team first installed the base Brock YSR layer for ground stability, thermal insulation and optimal drainage, then hand-pulled and sewed the synthetic turf over the shock-absorbing layer.

MRI Machines @ USC Stevens Institute for Neuroimaging and Informatics

Working closely with renowned neuroscientist Dr. Arthur Toga and his colleagues, MATT’s team helped to install a pioneering MRI machine during their renovation and retrofit of USC’s Burrell O. Raulston Memorial Research Building. The Mark and Mary Stevens Institute for Neuroimaging and Informatics leverages advanced imaging technology to examine neurological function and dysfunction, with the hope of developing ways to combat degenerative diseases and debilitating conditions, such as Alzheimer’s and schizophrenia. The newly built Center for Image Acquisition is a one-story MRI facility, housing a 13-ton, 3-Tesla MAGNETOM Prisma MRI and a 7-Tesla MAGNETOM Terra. The Terra represents the first of its kind in the US. MATT worked with specialists from ETS Lindgren to develop safeguards against intense magnetic fields generated by the machines, which can disrupt pacemakers and attract oxygen tanks. The scanner spaces resemble shoeboxes fitted within one another, utilizing silicon steel and copper layers.

First Net-Zero-Ready Building @ CSULB College of Continuing and Professional Education

This ambitious, sustainability-driven design-build facility marks the first net-zero-ready energy classroom building in the California State University system as well as the first new building on campus in nearly a decade. To meet the high standards required of such an environmentally forward venture, the team introduced energy-conscious elements into nearly every aspect of construction. Power sourced from rooftop PV panels and a 150-foot canopy, radiant floor heating and cooling systems to optimize climate control and an air flow-efficient layout all contribute to minimizing the need for traditional air conditioning or heating solutions that would normally tax the electrical grid.

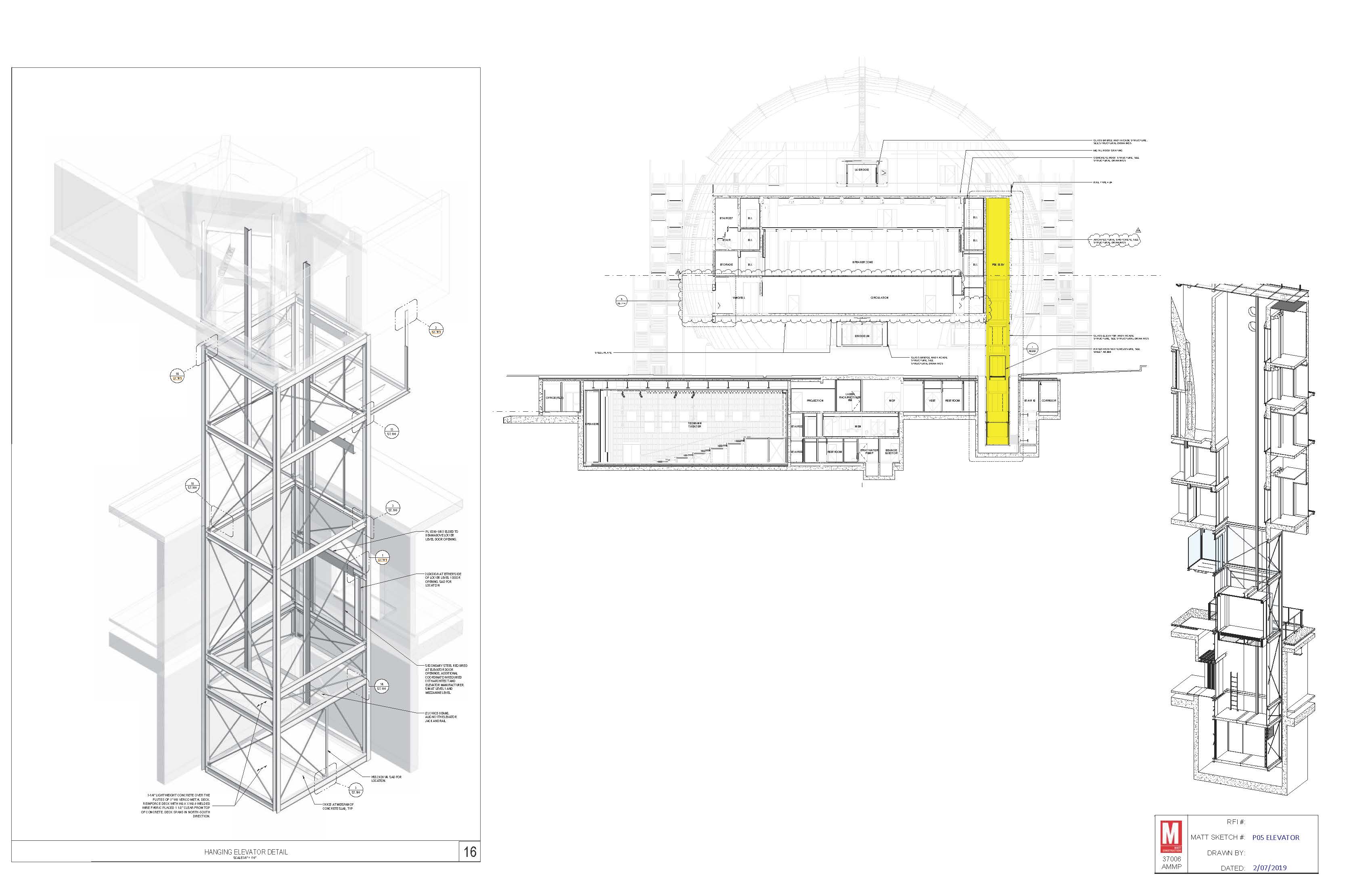

Hanging Elevator System @ Academy Museum of Motion Pictures

AMMP’s 1,000-seat Geffen Theater features an unusual roped hydraulic elevator system. The theater’s spherical design and seismic requirements led to the suggestion of leveraging this innovative alternative method of suspension, and it was up to MATT and its team to carry out the epic installation — a first for most of the team. The elevator dangles from the ceiling not unlike a forearm from a horizontal elbow, allowing it to move with the base-isolated sphere structure in the event of an earthquake. The crew worked closely with elevator and structural steel subcontractors to decide where to place the elevator’s control room and how to rig it within the massive space.

BubbleDeck @ Harvey Mudd College’s R. Michael Shanahan Center for Teaching & Learning

Boora Architect’s innovative vision for the new facility’s construction, the BubbleDeck (a voided slab structural system) reduces traditional slab concrete by 30%, replacing it with air-filled plastic bubbles that save in material and transportation costs. The lightweight material retains the strength of its 100% concrete counterparts while surpassing them: it allows for longer spans between columns and more open interior spaces. The BubbleDeck implementation at Harvey Mudd marks the most complex in the world and presented a unique design collaboration and teaching opportunity for the college’s engineering department.