Virtual Design & Construction (VDC)

We use VDC to supplement and enhance the approach we apply to every new challenge.

At MATT, we recognize that the success of every project depends on people. Even when we’re integrating innovative technology into the equation, it’s about assembling the right team and establishing a process and workflow.

How VDC Works For Us

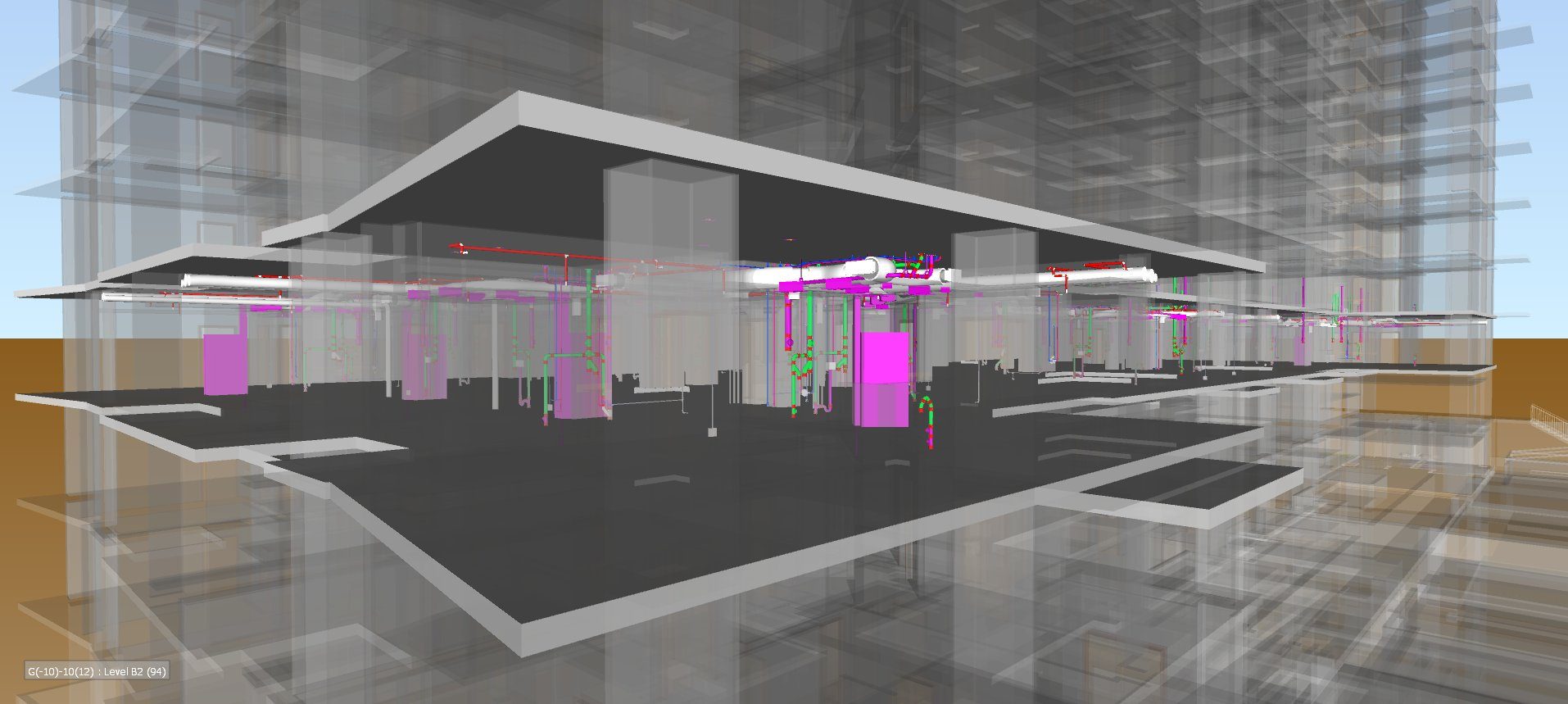

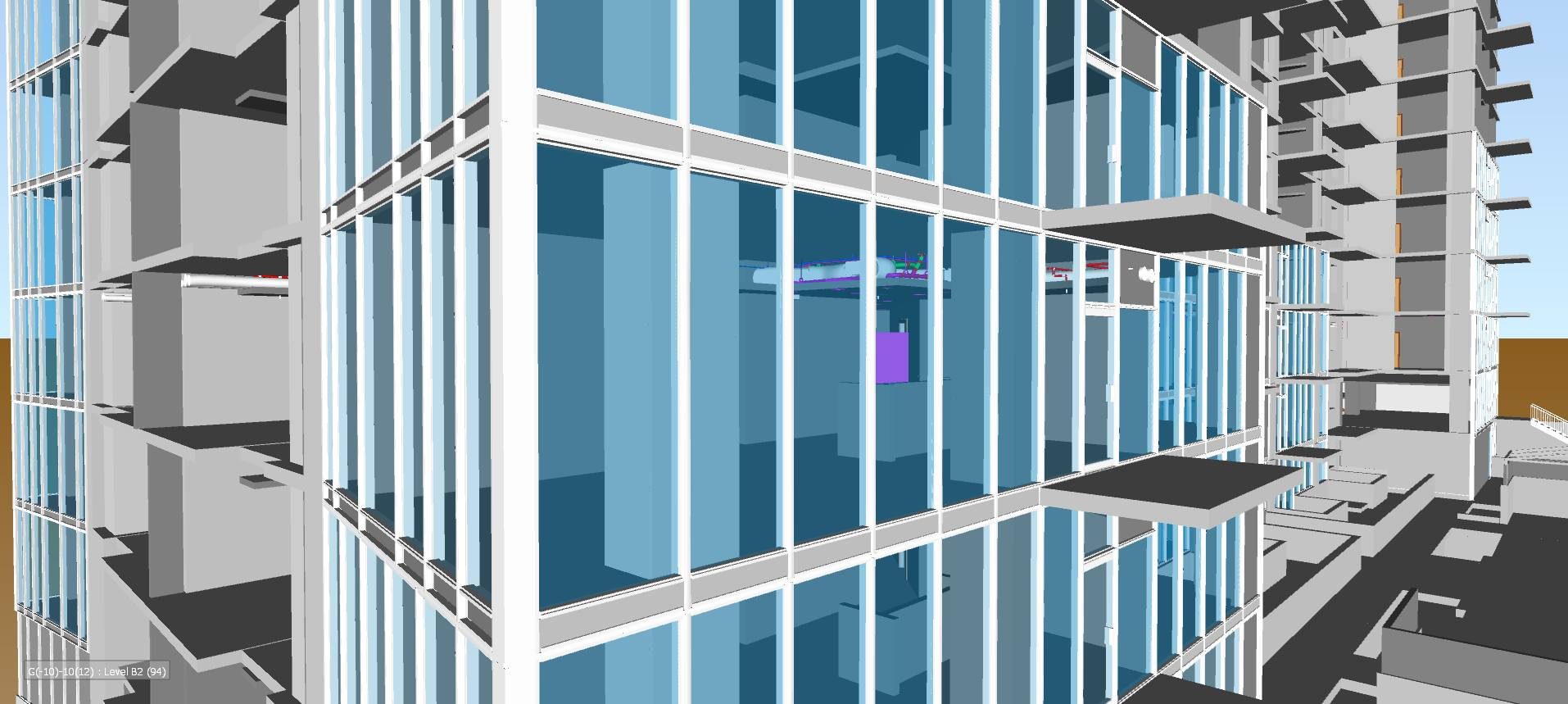

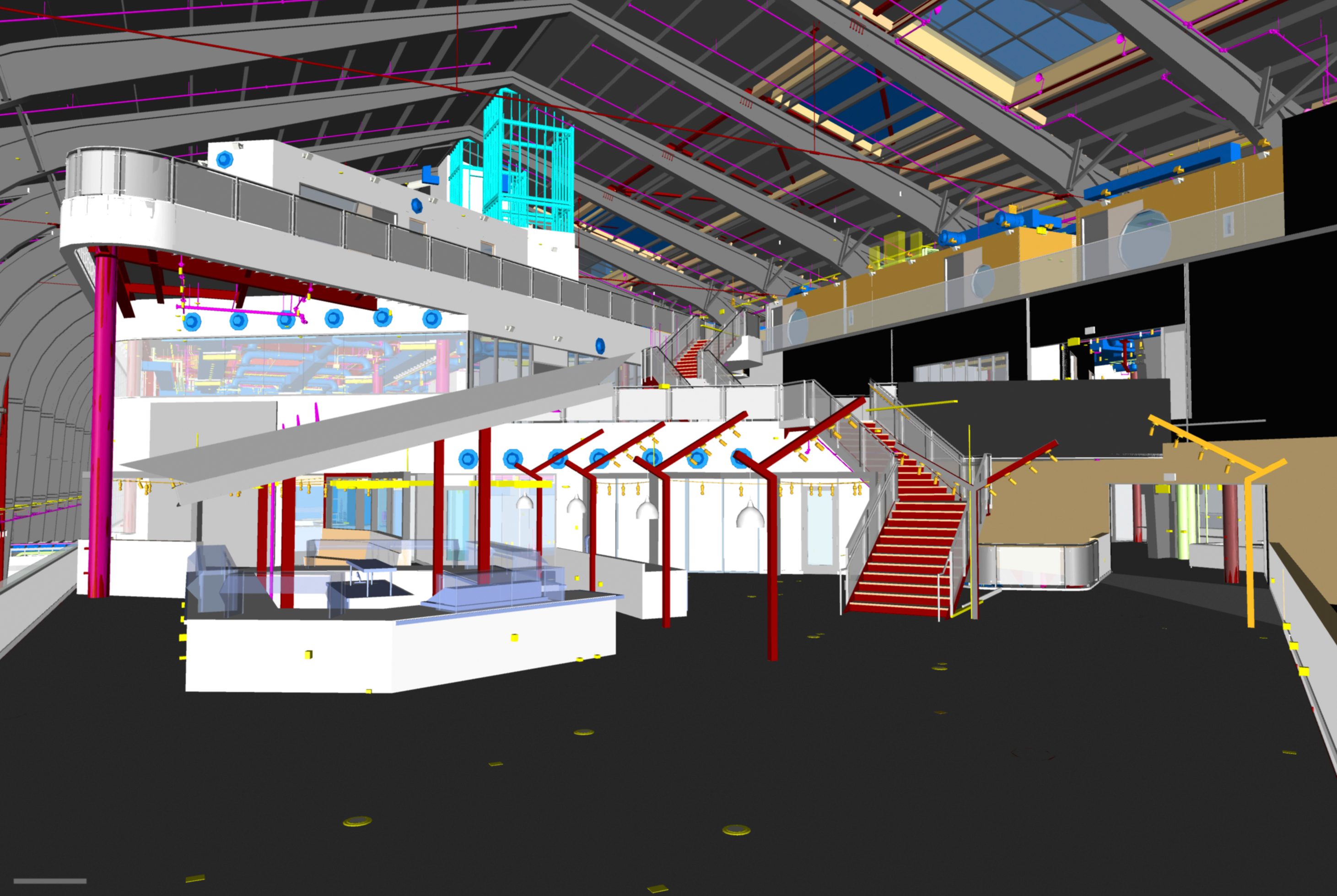

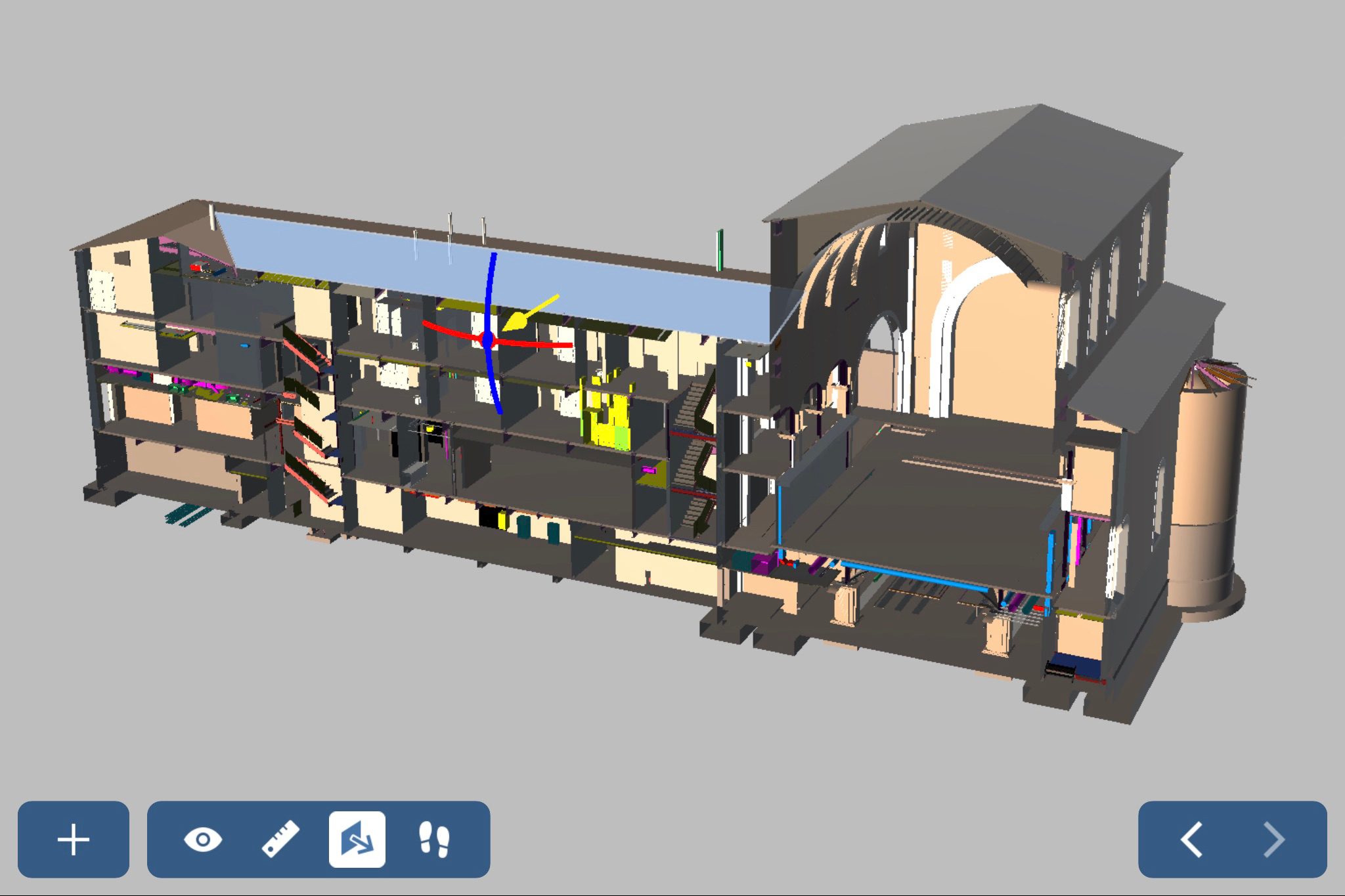

Construction begins in the virtual environment. First, we become engaged with the design team at the owner’s earliest invitation. The design team shares the models using software like REVIT, which we then import into Navisworks to kick off the coordination process.

As we’re developing the construction model in-house, we map out every possible area of consequence to the site. That means the site itself, adjacent properties, buildings, streets, sidewalks, trees and utilities. Any or all of these environmental factors could impact site access or constrain construction activity.

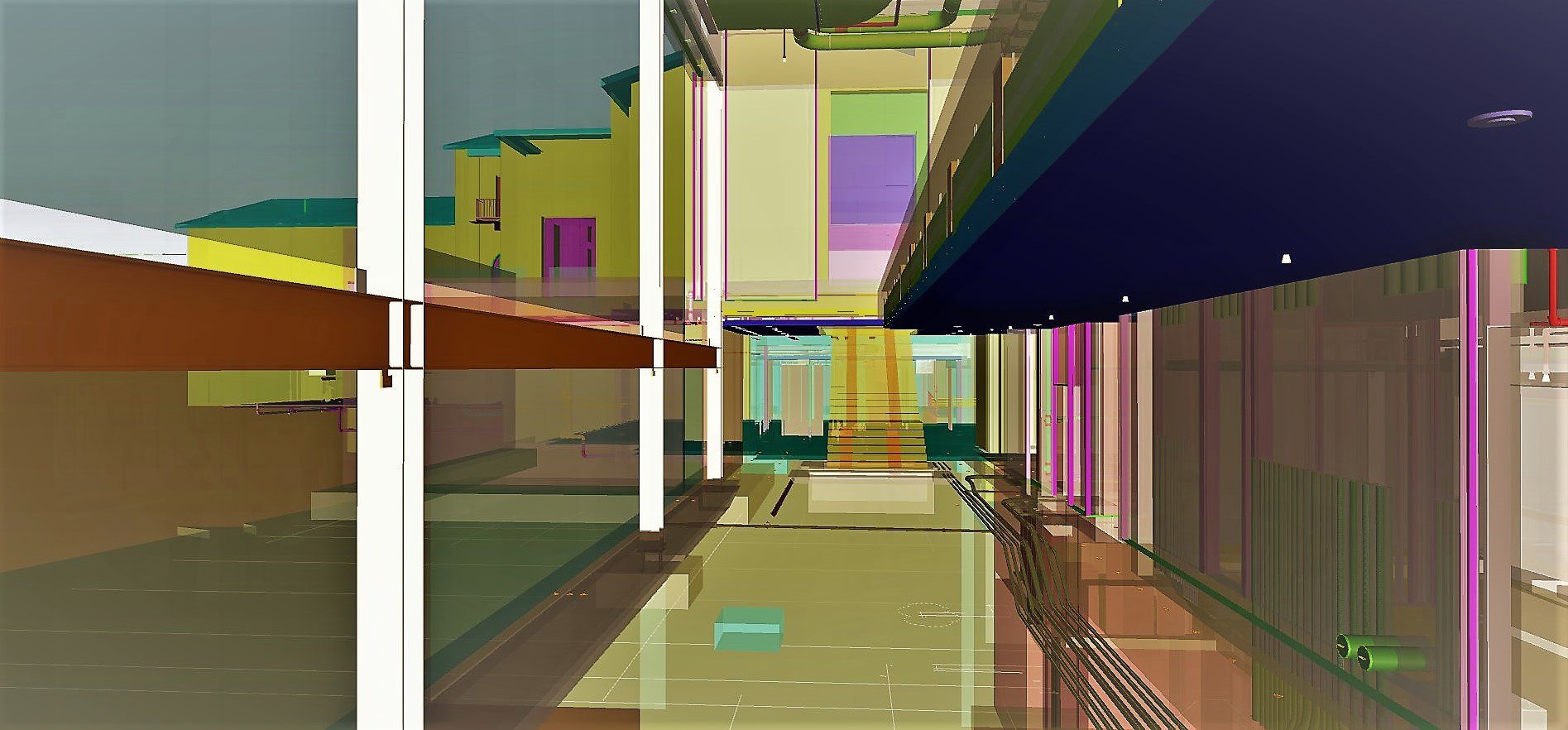

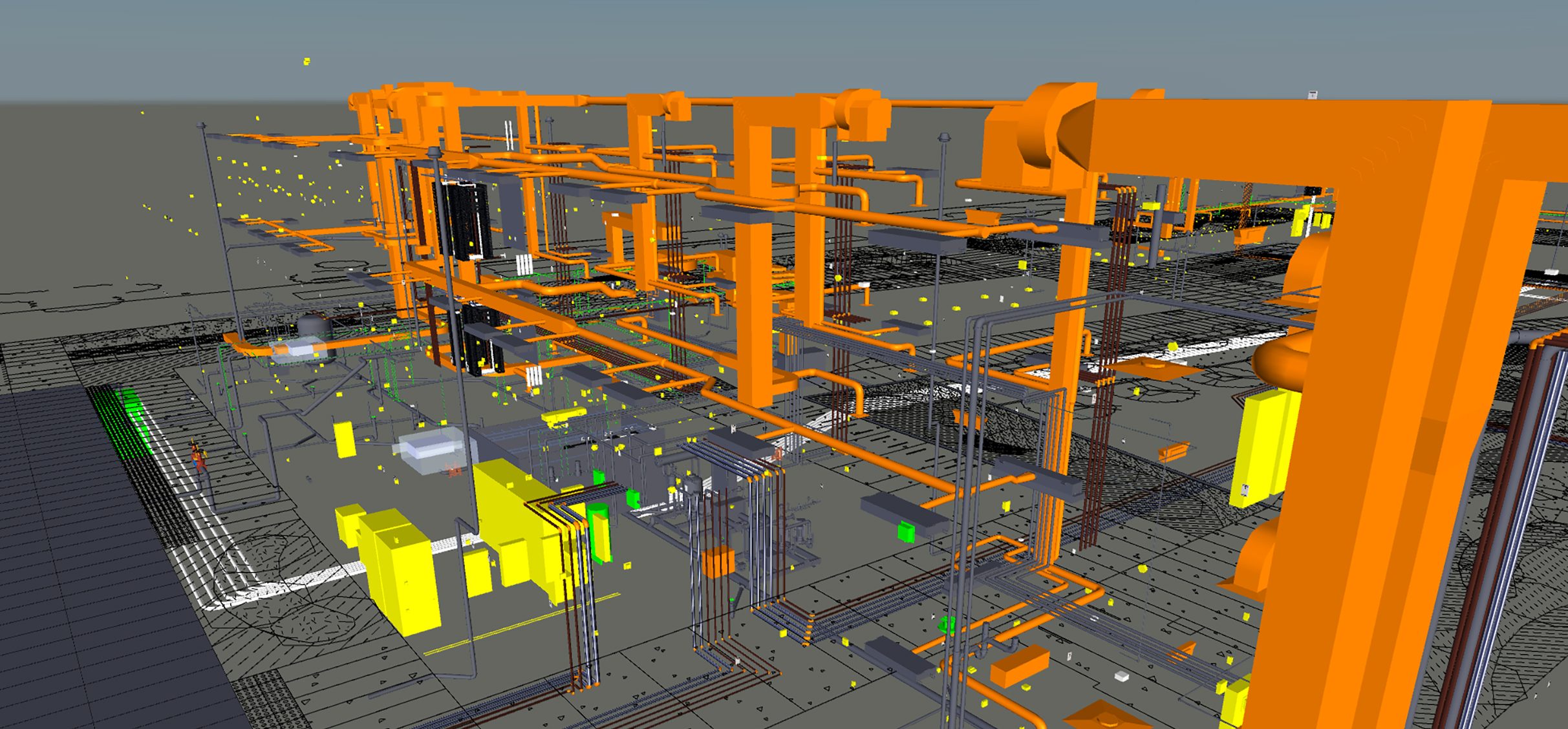

Navisworks lets us work with multiple model formats and different aspects of the design so that mechanical, electrical, plumbing and other trades can run clash detections with structural and architectural elements. If we see materials overlapping in the digital environment, we coordinate well ahead of construction and resolve the clashes in the virtual environment. Without this proactive, collaborative workflow, we could discover an obstacle in the field that would then take extra time and money to troubleshoot. VDC technologies save us from these potential setbacks.

The model becomes the primary basis and means of communicating ideas and logistics to everyone involved, from ownership, to design team, to agencies, to subcontractors. Frequent interaction with the model and weekly updates keep the process smooth and streamlined.

3D Modeling Program Rundown

Drag the center toggle to reveal before/after views

Revit

Popular with architects during the design phase, REVIT allows users to design a building in 3D. REVIT is the most prominent modeling software in the construction industry for its efficient interoperability across most VDC technologies. MATT also uses REVIT in house to produce 3D models from 2D conceptual design documents to analyze the constructability of building systems with designers and clients. See project here.

Drag the center toggle to reveal before/after views

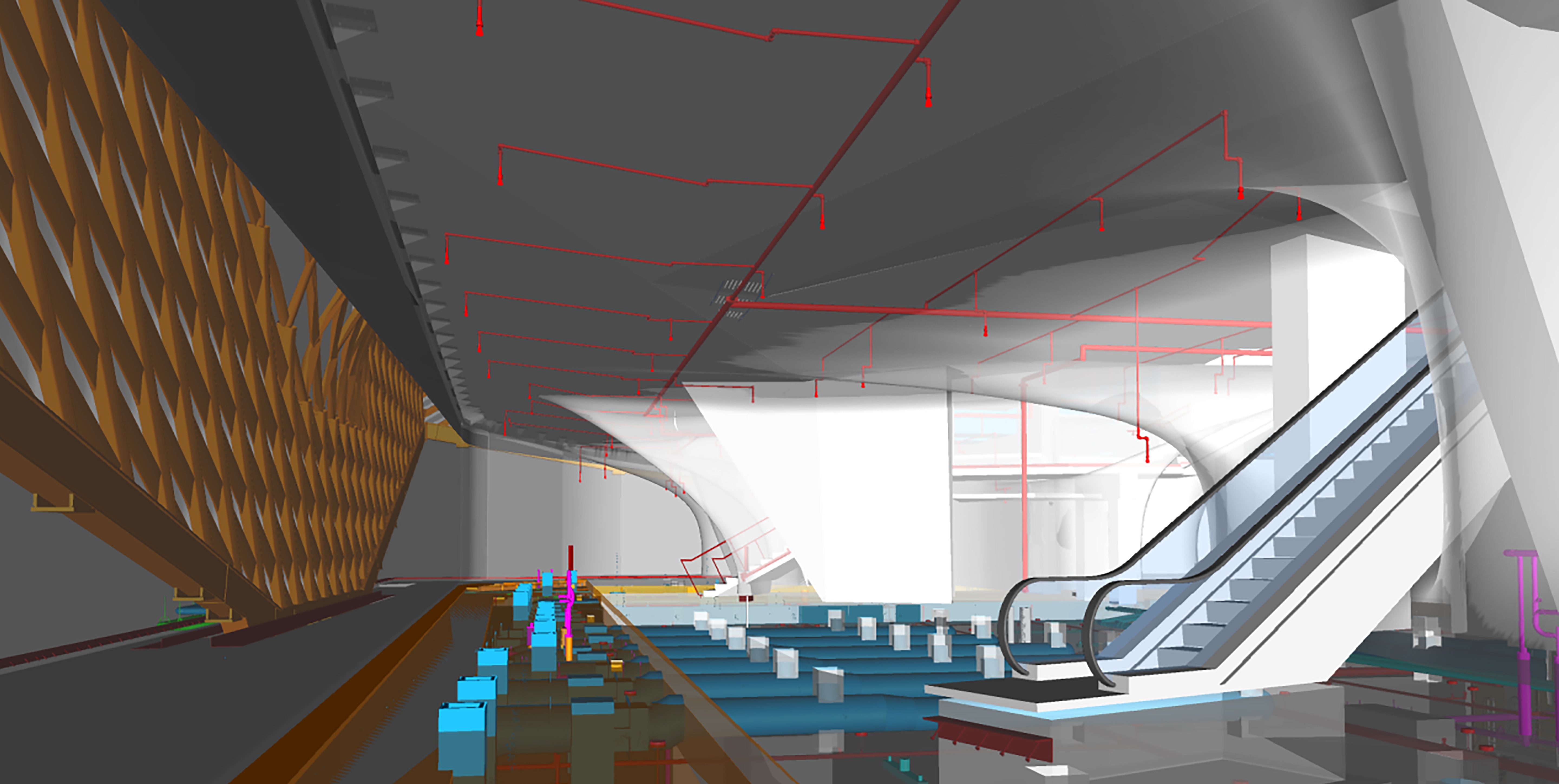

Digital Project

An alternative to REVIT, Digital Project allows architects to develop models regardless of geometric complexity with powerful surface, wireframe and solid modeling. It was used at the Petersen Automotive Museum and for The Broad museum. It can address localized conditions and incorporate automated drawing generation, optimization and reporting. It also allows you to clash, scale, combine 2D and 3D environments, navigate, and build 4D sequences. See project here.

Drag the center toggle to reveal before/after views

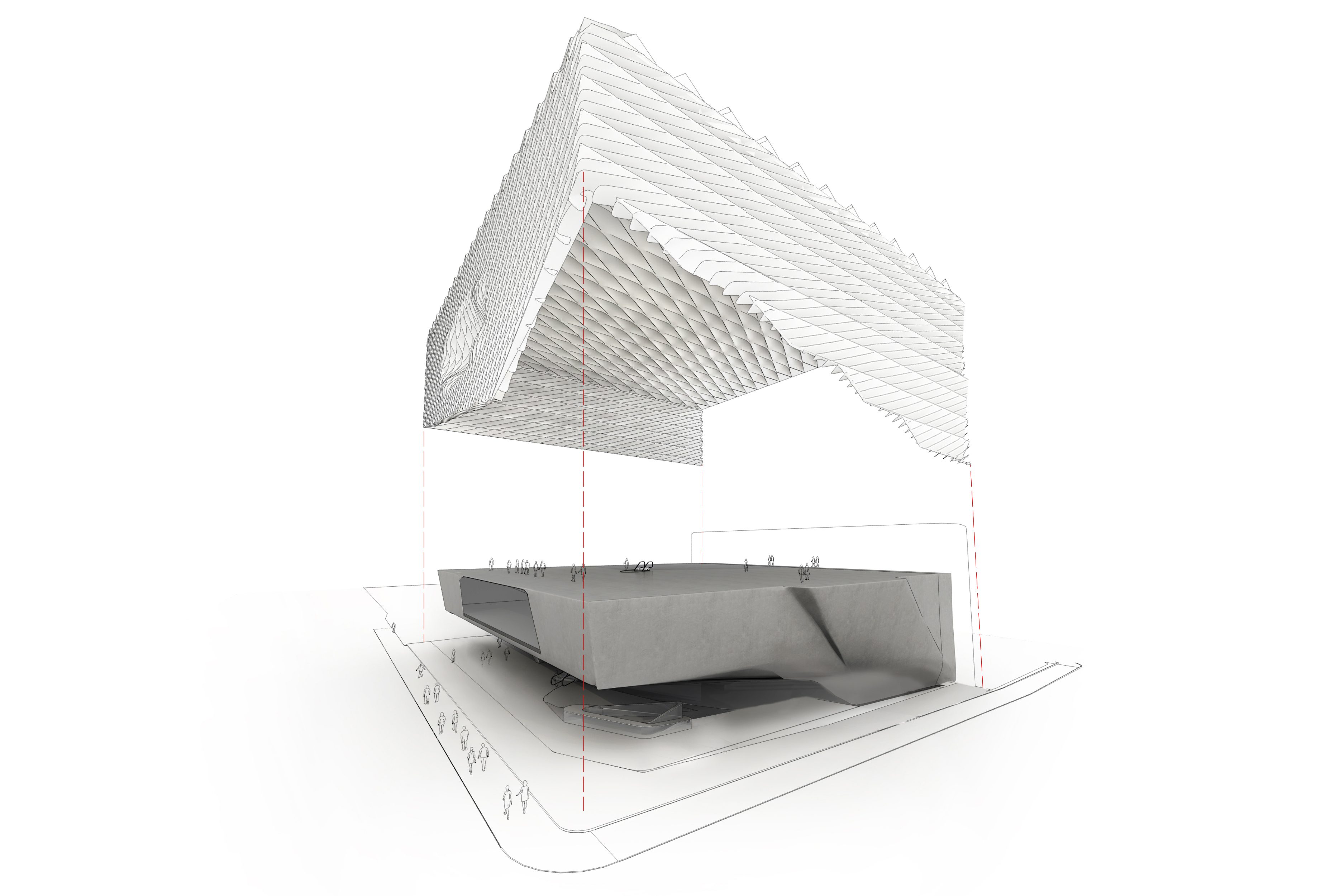

RHINO

Uses a NURBS mathematical model to produce precise curves and freeform surfaces (rather than polygonal mesh-based applications). For an architect, it’s a better tool for complex shapes beyond walls and floors, allowing the designer to map out more organic curvaceous surfaces. MATT uses RHINO for coordinating design intent and quantifying materials to estimate cost. See project here.

Drag the center toggle to reveal before/after views

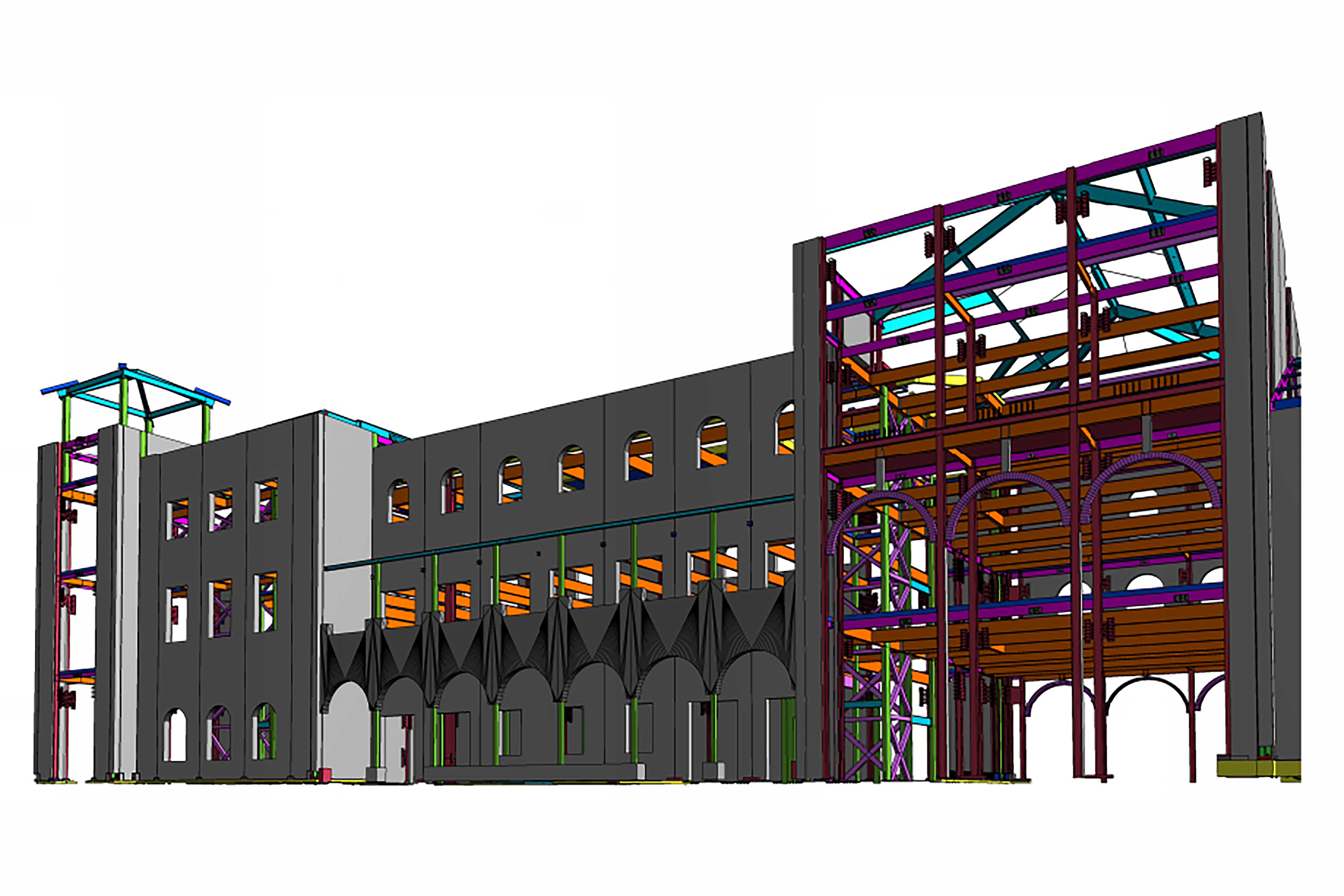

TEKLA

A highly collaborative tool primarily used by steel subcontractors, it has the ability to model different materials (concrete, timber, steel), can handle large and complex structures, create accurate constructible models and flow from the design phase to the construction site. Used often for steel and concrete detailing, it guides users from concept to fabrication. Often used alongside REVIT, its primary benefit is fabrication-level models and shop drawings for structural steel framing and reinforcing steel. See project here.

Drag the center toggle to reveal before/after views

Additional MATT Technologies

Navisworks

Allows users to open and combine 3D models to detect potential structural, MEPF and other clashes. It is the most popular of our diagnostic tools. The software can navigate a model in real-time and can run material clash reports, 4D schedule simulations and photorealistic rendering, making it a valuable asset in preconstruction and construction. See project here.

Synchro 4D

A system that allows the user to link the construction schedule to elements in the model, then can run simulations to show what the project will look like at any given point in time. A very useful tool for identifying and working out sequencing challenges. See project here.

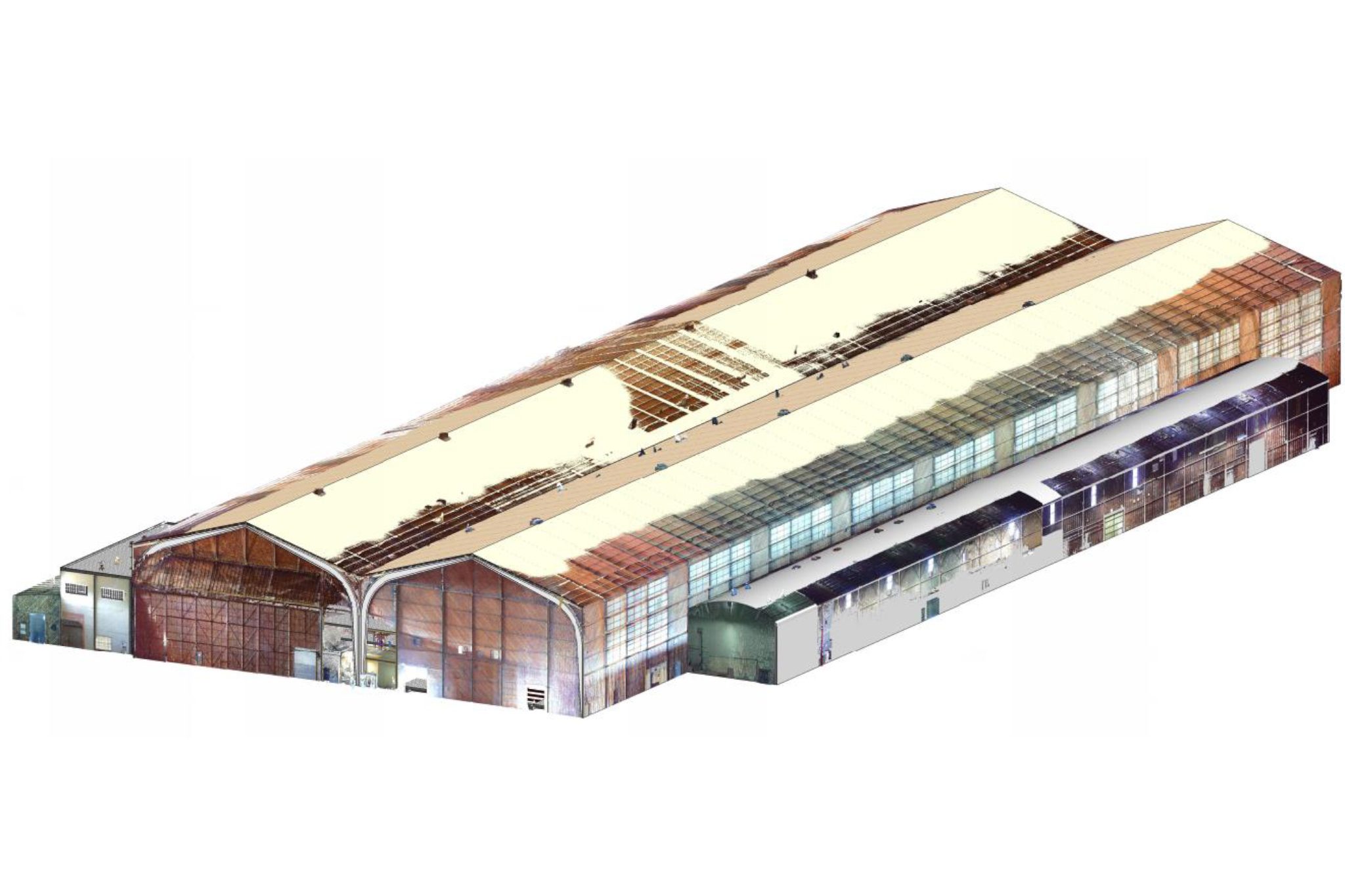

Point Cloud Data

This laser scanning apparatus scans an existing structure, then creates a point cloud as a digital representation of the conditions within. It’s very useful for renovation projects. In such cases, this kind of scanning allows an architect to account for structural features that might otherwise only reveal themselves during construction, avoiding potential scheduling delays. See project here.

Procore

Procore allows us to publish the coordinated BIM model straight from Navisworks to the cloud and access it out on the jobsite with a smart device. With this tech, our field can navigate the jobsite with the BIM model in hand to aid design and constructability conversations with the client, design team and subcontractors. Having the model on the same platform as our project management documentation allows for increased efficiency as we can reference construction plans, RFI’s and shop drawings concurrent with the 3D model. See project here.

Augmented Reality

Allows users to bring the 3D model into the field. Users can look at the design to be constructed overlaid on the actual site conditions. This technology was used at the Academy Museum of Motion Pictures to set control lines on the inside of the sphere and to understand where the theater walls needed to be in relation to those control lines. See project here.